After last night's Daleking, I pondered ways by which I wanted to attach the wheels to the fender. I got to looking more closely at them, and it became obvious that there was only one way to attach them. The two motors each have three mounting points arranged in a triangle, and a "freewheel" lever that disengages the wheels from the motors (if both are toggled). I wanted that level accessible and I needed to attach two of the three mounting points to flat, steel tubing.

I drove out to Metal Supermarkets in Kent, Washington and picked up around 20 feet of hot-rolled square steel tubing, and 10 feet of flat steel (1" x 0.125"). The latter I did not use in today's adventures, but I will be using it on the top of the fender to reinforce what I did today. I also swung by my neighborhood Lowe's (many, many times today, as it turned out) to get a new metal-cutting blade for the miter saw, and metal-drilling bits for the drill press.

After cutting off a portion of steel tubing based on the length of the fender interior, I drilled it to match the two mounting points I had selected. I also cut a hole to accommodate a portion of the tire and motor. It became glaringly obvious that my plan of bolting the square tubing directly to the fender wouldn't work—the wheels were much too small. I stacked and stacked 1/2" offcuts of wood to get it to the height it needed to be for a good 2" of clearance from the fender base. The stack was roughly 3.5 inches, bringing the length of tubing just about level to the fender base.

Back to Lowe's I went, this time for some (inaccurately named) 2x4s. These beams of wood are actually about 1.5" by 3.5", but it was the same height as my stack. I had the friendly store employee cut me up some three-foot lengths, and I also selected washers, nuts, and some hex-bolts of various lengths.

I got back home, and, since it was a beautiful day yet again, I took everything outside. I placed the offcuts of the beams inside and placed the wheel assemblies on top to see if my madcap plan would work. I was pretty happy with the result, but I still wanted to strengthen the fender with a framework of steel beams.

I cut, drilled, and attached three lengths of steel to the center, left, and right side of the fender. Then, to get the best of both worlds, I made dado (housing) cuts in each of the wooden beams using the table saw to fit over the steel beams. Next, I aligned my hand drill to the holes already cut in the steel beams, and continued drilling the rest of the way into the wood. Then I took 5-inch long hex-bolts and secured them to the frame. I make is all sound so simple; however, this part of the assembly took me awhile, from inception to execution.

This was all ad-hoc thinking on my part. No plan.

I debated whether or not to trim the long lengths of steel tubing from the wheels since the two wooden beams I had attached weren't that far apart. In the end, however, I decided to go overkill. I repeated the above process and attached two more wooden beams: one closer to the front, and the other closer to the rear. I figured that this way, the weight placed on the fender from the rest of the Dalek—including the batteries, skirt, shoulders, neck, head, extra bits, and, of course, me—would be more evenly distributed along the fender frame.

(The "L" brackets that can be seen in the pictures are right now just for show, but I plan on further securing the wooden beams to the fender with them next time. I also plan on adding four more lengths of steel bar—one on either side of the two center wooden beams—then bolting them to the wood beams and steel beams attached to the wheels. This will give added strength to, and further secure, the wheel assemblies.)

With all the gubbins that I attached underneath, I was very pleased at how clean everything was up on top. When I took it back to the garage for the evening (man, that things weighs a lot more now), I placed it in its normal position flat on the floor and stood on it. Then I walked all over it. There wasn't a creak to be heard, and it felt very solid. This was also with the wheel assemblies removed, so it will be another story altogether when I add those, along with appropriately-sized caster wheels in the front and back.

Now, I'm not an engineer by any stretch of the imagination. This was a very ad-hoc approach to solving the problem of how to mount small wheels with bizarre mounting points. I've tried to over-engineer my ideas as they came to me, but if anyone can see any problems that are glaringly obvious, I would be much obliged.

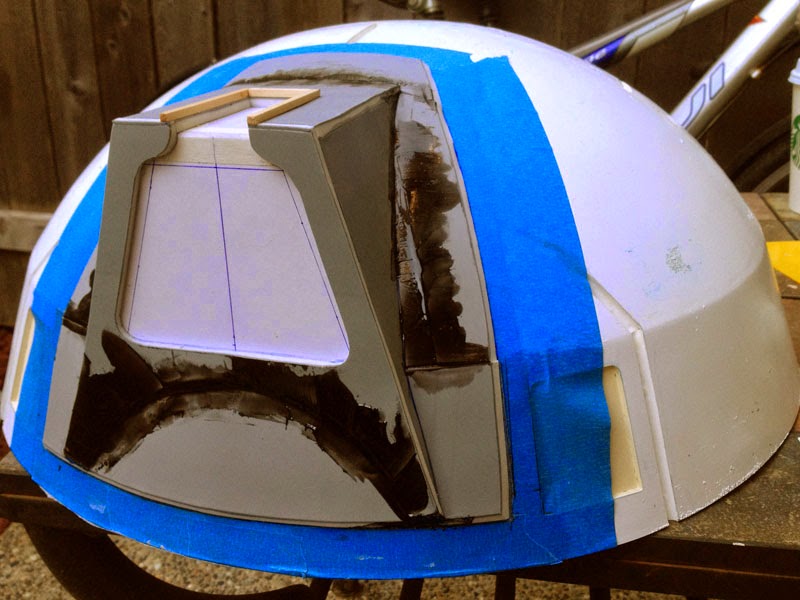

Additionally, the linoleum didn't behave like the plumber's rubber I used for the dome indentations. In the case of the red plumber's rubber, the inserts peeled off the gel-coat with the greatest of ease (I even had forgotten to use release agent on them). With the linoleum, it started to separate from itself, leaving bits stuck to the gel-coat. The rippling effect is very prominent, as well, but I'm not too concerned with that. Once I made a cowl from this mold, I'll just sand that down before priming.

Additionally, the linoleum didn't behave like the plumber's rubber I used for the dome indentations. In the case of the red plumber's rubber, the inserts peeled off the gel-coat with the greatest of ease (I even had forgotten to use release agent on them). With the linoleum, it started to separate from itself, leaving bits stuck to the gel-coat. The rippling effect is very prominent, as well, but I'm not too concerned with that. Once I made a cowl from this mold, I'll just sand that down before priming.