After that cured—which was pretty quick—I took out the Minwax oil-based polyurethane varnish that I had also used to coat and seal my dome plug months ago. I applied a couple of coats every 4-6 hours or so, around the time each coat got tacky. Then I left it to dry overnight. In the morning, I noticed that it was still tacky, so I left it sit while I was at work. Still tacky. After chatting with acrodrome, I learned that there was no area for the oils in the varnish to soak into, linoleum being non-porous. I was thinking that I needed to clean the whole thing off with mineral spirits, or, worse, scrap it all and start over. For the third time. But then, the weather turned very sunny, and I left it out in the brilliance for several more hours. It finally cured!

After that cured—which was pretty quick—I took out the Minwax oil-based polyurethane varnish that I had also used to coat and seal my dome plug months ago. I applied a couple of coats every 4-6 hours or so, around the time each coat got tacky. Then I left it to dry overnight. In the morning, I noticed that it was still tacky, so I left it sit while I was at work. Still tacky. After chatting with acrodrome, I learned that there was no area for the oils in the varnish to soak into, linoleum being non-porous. I was thinking that I needed to clean the whole thing off with mineral spirits, or, worse, scrap it all and start over. For the third time. But then, the weather turned very sunny, and I left it out in the brilliance for several more hours. It finally cured!

(In hindsight, I probably didn't even need to do this step. I remember when I had applied the rubber panels during my second dome attempt, and had neglected to even spray release agent into them, and they turned out just fine in the end. Rubber and gel-coat seem to work well together.)

So, after that, I sprayed it down with silicone release agent and mixed up a small batch of gel-coat with some dye in it. I added the catalyst, stirred, and sponged it on pretty liberally. And, after a few minutes from finishing up, those weird chemical reactions happened again, like what happened when I was making the dome plug months ago. So strange. I wonder if it's the Minwax that somehow causes it.

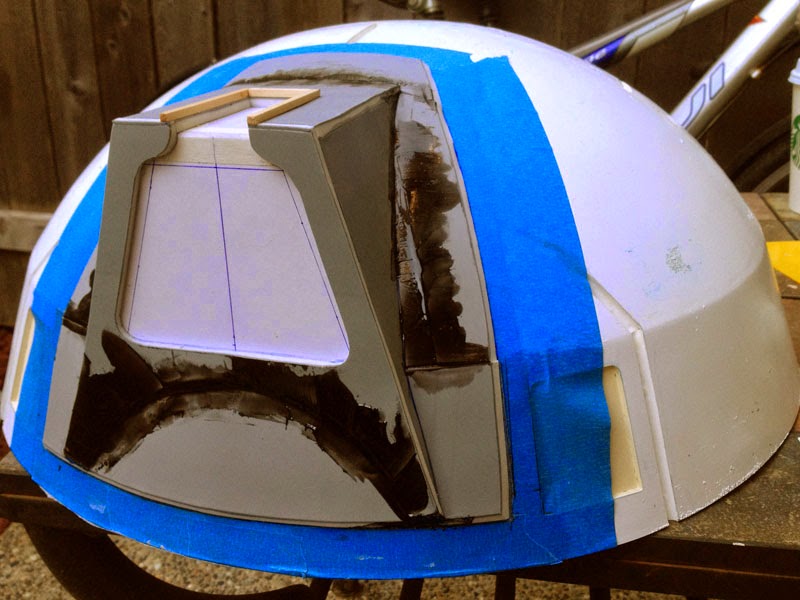

So, after that, I sprayed it down with silicone release agent and mixed up a small batch of gel-coat with some dye in it. I added the catalyst, stirred, and sponged it on pretty liberally. And, after a few minutes from finishing up, those weird chemical reactions happened again, like what happened when I was making the dome plug months ago. So strange. I wonder if it's the Minwax that somehow causes it. While that was getting nice and tacky, I tore off some pieces of surfacing veil and chop mat from their respective rolls. I was really hoping that I wouldn't run into a problem with air bubbles given all the sharp angles. It was starting to get darker outside, so I didn't let the gel-coat get as tacky as I would have normally wanted it.

While that was getting nice and tacky, I tore off some pieces of surfacing veil and chop mat from their respective rolls. I was really hoping that I wouldn't run into a problem with air bubbles given all the sharp angles. It was starting to get darker outside, so I didn't let the gel-coat get as tacky as I would have normally wanted it. I spent most of the early evening and night applying the glass—two layers of the surfacing veil, and two layers of the chop mat (give or take). I tried to work out the air bubbles as much as possible, and give good coverage to the cowl plug (especially on the sharp corners). I put it back in the garage, turned on the heater, and left it to sit for another 24 hours.

I guess we'll see how it turns out tomorrow! *crosses fingers*